Why Production Quality and Testing matter in dvLED Displays

When evaluating dvLED (direct view LED) displays, it’s tempting to focus on specs including resolution, brightness, and price. But the real differentiator between a display that simply looks good today and one that performs flawlessly for years, lies in how it’s built and tested.

At Sharp, we believe that delivering long-term value to customers starts far earlier than installation. It begins with rigorous attention to production quality, precision manufacturing, and extensive testing. Cutting corners in these areas invariably leads to costly consequences later.

Watch the video as Graham Kirkpatrick and Simon Hayes explain the importance of quality.

Quality starts with the Diodes

Every LED display is made up of thousands, or even millions, of tiny light-producing components called diodes. The uniformity of these diodes directly impacts how consistent and accurate the display appears.

Binning is the process of sorting LEDs by brightness and colour, and it is an essential step in production. Without it, inconsistencies become visible across panels, particularly on larger screens. Sharp uses high-grade, carefully selected diodes to ensure that every display we produce is consistent and reliable across its entire surface.

Binning is the essential process of sorting LED diodes by brightness and colour

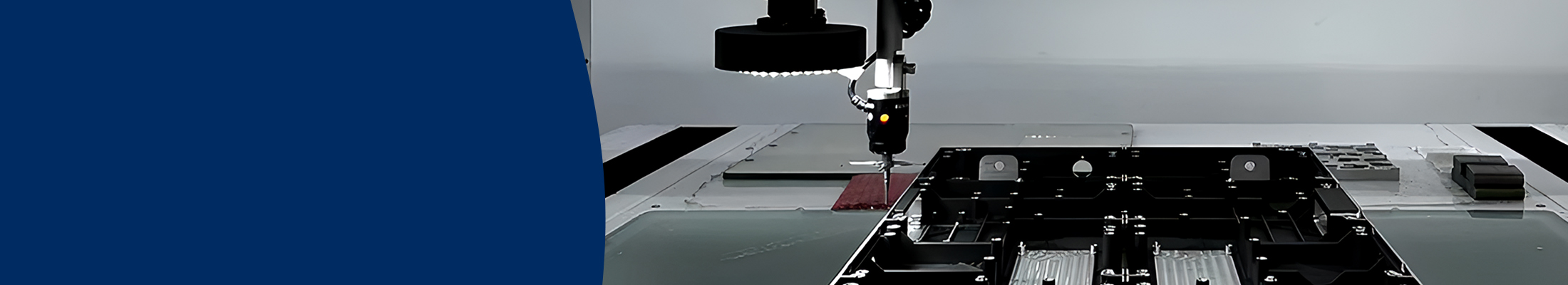

Precise mechanical calibration ensures perfect module alignment

Precision manufacturing makes a visible difference

When panels are assembled, they must align with microscopic precision. Even slight mechanical variances can lead to visible seams or image distortion once installed. Sharp applies strict mechanical calibration throughout the production process to ensure every panel fits perfectly with its neighbours, delivering the seamless, professional visual experience our customers expect.

This level of attention to physical tolerances doesn’t just improve image quality, it also simplifies installation and reduces time on site.

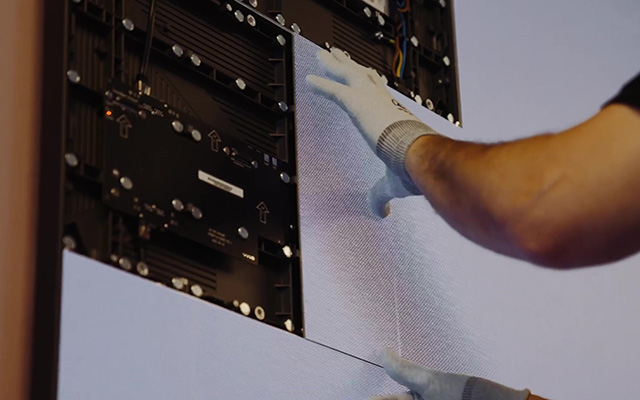

Testing isn’t optional, it’s essential

Every Sharp LED display undergoes a 72-hour burn-in process before it leaves the factory. During this time, the display is run at full brightness through various colour and pattern cycles to detect any early diode failures. Any defective pixels are repaired and recalibrated on the spot.

This up-front testing dramatically reduces the likelihood of early-life failures, helping our customers avoid unnecessary downtime and maintenance after deployment.

Before leaving the factory, LEDs undergo a 72-hour burn-in test

EMC Class B compliance is essential in airport environments

EMC Compliance: the invisible risk

Large LED installations can emit electromagnetic interference (EMC) if not properly designed and shielded. This interference can affect everything from WiFi networks to critical medical or security systems.

That’s why Sharp designs its displays to meet EMC Class B compliance, the highest standard for emissions control. This level of testing is especially important in sensitive environments like airports, control rooms, and public spaces where reliability is non-negotiable.

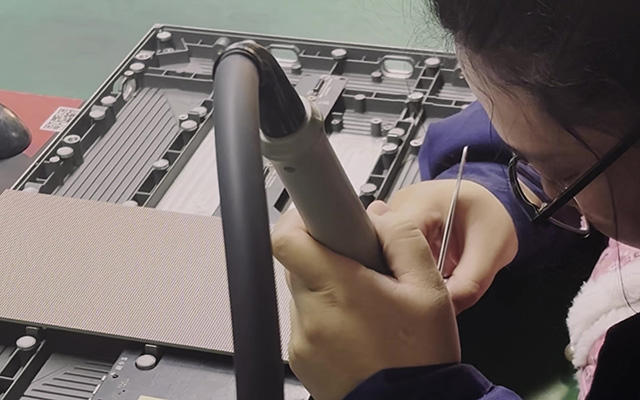

True craftsmanship

While automation plays a key role in modern electronics manufacturing, many of the final steps in LED production are still done by hand. Skilled technicians perform visual inspections and manual calibration to ensure pixel-perfect performance.

At Sharp, our teams bring years of specialised experience to the table. This human touch, combined with engineering precision, is a big reason our displays stand apart in terms of quality and longevity.

Every LED panel goes through a manual quality control inspection

Why it matters to you

Choosing an LED display isn’t just a technical decision, it’s a long-term investment. A display that hasn’t been properly manufactured or tested might perform well initially but is more likely to develop issues over time.

When long lasting performance, reliability and compliance cannot be compromised

When you choose Sharp, you’re choosing:

- Components that are selected for consistency and reliability

- Engineering processes that ensure a seamless, professional result

- Testing that validates performance before your display is even installed

- Compliance that protects your environment from interference

In summary, you’re choosing peace of mind.

Your partner in display excellence

At Sharp, we’re not just a supplier, we’re a partner. Our goal is to empower customers to make informed decisions about their display investments by sharing what truly impacts quality, reliability, and performance.

If you're in the market for an LED display, we recommend you look beyond the brochure specs. We’re here to help you understand what really matters and why it pays to choose a provider that values quality at every stage.